Powerful, easy-to-use, & customizable cloud-based Retail ERP System with a world-class UAE-based support team.

GROW YOUR RETAIL BUSINESS USING UAE'S MOST PROVEN TRUSTED CUSTOMIZABLE EFFICIENT SCALABLE AFFORDABLE ERP SYSTEM

Latest UAE Success Stories

TRUSTED BY 100+ UAE RETAILERS

Inventory Works Both Online & Offline

Keep track of all your items with low stock alerts, the system stays reliable even if your connection is not.

Checkup On Your Business From Anywhere

All your real time sales data on your finger tips.

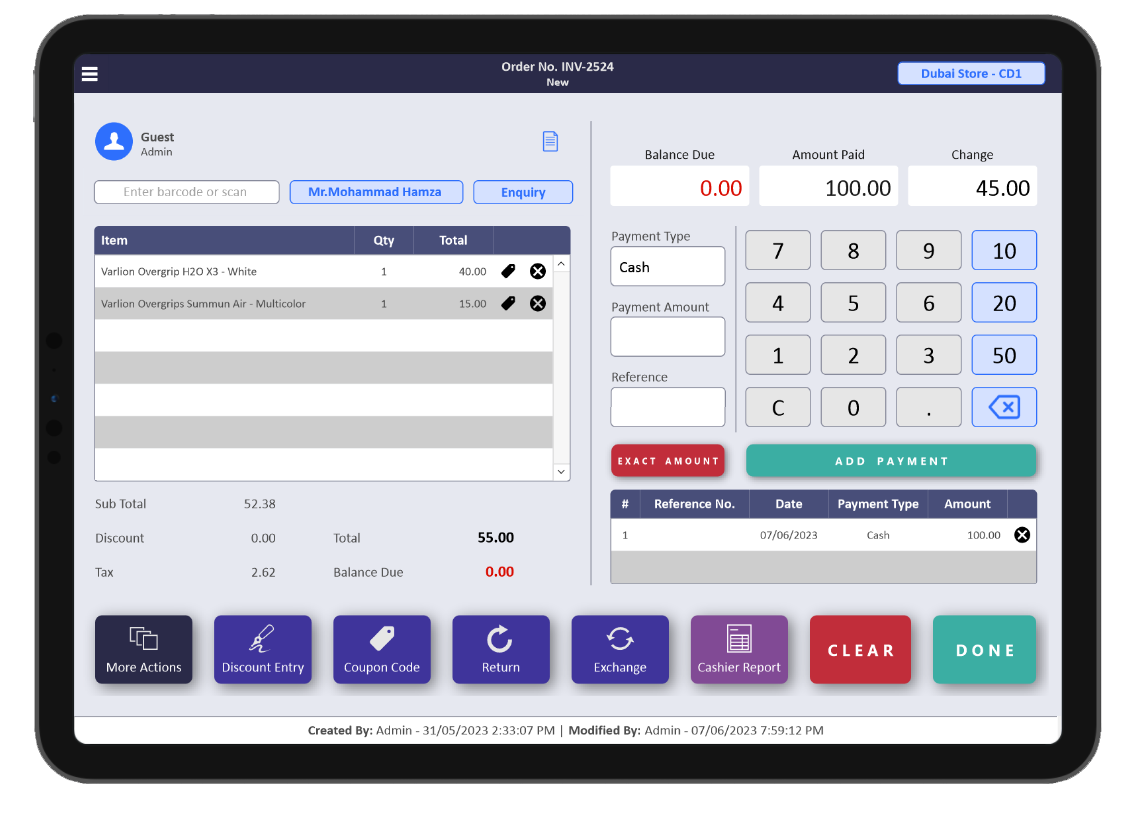

Easy To Use POS

Set-up in minutes, sell in seconds & compatible with any device.

Your Business In Your Pocket

Track the health of your business from anywhere in the world with just your mobile phone.

Simple & Beautifull

Say goodbye to ugly, expensive, outdated POS systems and enjoy an interface designed for modern retailers.

Inefficient inventory and stocks are costing you time, money, and sales.

Fly through your busiest days with an agile & fast POS System

Get real-time reports that help you boost your sales and prevent losses.

Maximize customer lifetime value with a personalized marketing campaign.

UAE Based Development Team

Hulexo’s entire development team is present in Abudhabi, Khalidyah & DTEC, Dubai.

UAE Based Support Team

We also have an onsite & virtual support team in both Dubai & Abu Dhabi with 24/7 Service to ensure business continuity.

Built For Middle Eastern Retailers

Automatic updates of your database in full compliance with the latest changes in the UAE legislation, including newly regulated VAT reports & more.

Approved By UAE Federal Tax Authority

Hulexo has been approved as a provider of the VAT-compliant software by the UAE’s Federal Tax Authority.